2023 World Coffee Roasting Championship

| RI

Table of Contents

The competition was hosted at the Taiwan International Coffee Show, which brought massive interest for the roasting category, with a constant spectator crowd around the screens. Cropster is honored to sponsor this event by providing the roast logging software, for not only the world championship but many national qualifiers.

The World Coffee Roasting Championship, like other coffee competitions, was created to be a knowledge-sharing platform and professional inspiration for roasters and their industry. We at Cropster believe in collaboration and that sharing information makes everyone better, which is why we are excited to share the winning roast curves and other details of this year’s challenge. So please welcome the roast curves of the 2023 WCRC champions!

Results for the 2023 World Coffee Roasting Championship

1: Taufan Mokoginta, Indonesia, 561 points

2: Talha Erdinc Bas, Turkey, 550 points

3: Andrew Coe, United States, 527 points

4: Yoshiyuki Nakamura, Japan, 515 points

Huge congratulations to all competitors, and a heartfelt thank you to the organizers, judges, volunteers, and sponsors who made this event possible.

About the Competition

In the World Coffee Roasting Championship (WCRC), competitors are evaluated on three key elements: developing a roasting profile to highlight desirable characteristics of the provided competition coffee, the cup quality of the roasted coffee they deliver, and the accuracy of how that coffee tastes compared to what they forecasted on their Roast Plan. All this in two major assignments: a single-origin and a blend roast. We’ll give you a quick outline of the competition and why it is such a difficult challenge – if you know it, just scroll down to the curves.

Competition Details

Green Coffee Evaluation – The first clues

The competition starts with Lab Practice: this is when competitors can have their first look at the competition coffees, measuring screen size, density, and moisture content, as well as checking for defects. Green grading is not scored anymore at the world level, it is only for the competitors’ reference. They also receive key origin information (country, region, farm, altitude, varietal, and processing method) from the organizers just before the competition. If they are experienced enough, these details can already serve as clues for their roasting approach. There is one designated green coffee for the single-origin assignment and three different greens they must use for their blend (what will be their main component is up to them, but each green has to be used as a minimum of 10% of the blend.)

Sample Roasting and Cupping – The final clues

After lab time, competitors move on to Sample Roasting. This is their only time to see how the coffees behave before they have to go live in their production roast rounds. However, they don’t get much playtime: in Taipei, sample roasting consisted of 45 minutes, so literally one shot at each green. After sample roasting, they get to cup their samples, together with their coach. Whatever the teams assess here is going to be the foundation of the Roast Plan, a scoresheet that competitors have to submit with a complete description (aroma, flavor, aftertaste, acidity, sweetness, mouthfeel) of their final roasts, but before actually producing those roasts. One Roast Plan for single-origin and one for the blend.

The first day of the competition finishes with Practice Roast: an unscored round to practice on the production roast machine and with the Cropster software, but to keep it interesting, using a “playtime” green coffee, not the actual competition ones.

Production Roasting – What makes it or breaks it

The second and third day is showtime. Production Roasting is when all the roast plans go live; when competitors put all their knowledge into practice. Day two: all competitors produce their Single Origin roast. They have 30 minutes of competition time, which is usually enough for two attempts and some bean sorting. Most competitors produce a second batch even if they hit their goals in the first one, just to be safe. From the two, they can decide which one to submit but the decision has to be made promptly, based on roasting data and visual clues only. On day three, they repeat this but with a Blend. So they have to handle three different green coffees and an actual blending on the spot, which typically means more roast batches and more tasks to manage. They get 60 minutes for this round. Pre-blending? Post-blending? Which one would be safe to execute within these circumstances, and which one would result in the best possible cup? Both production roast rounds are incredibly interesting to watch: the different strategies, various sorting techniques, and smart multitasking. There are aborted roasts, psychological battles inside, and tangible tension in the air.

Evaluation – Judging and scores

One production roast is evaluated by three cupping judges and a non-scoring head judge. Only cupping judge scores count towards the total scores. They carry out an affective assessment, plus score the accuracy of the competitor’s previously submitted description. Most of the scores in WCRC come from these cupping and accuracy scores. You can have a closer look at both the scoresheets and the cupping protocol in the official WCRC rules here. This year, for the first time in WCRC, descriptions were done according to the SCA’s new Coffee Value Assessment system, which represented a significant change in both judges’ assessment and competitors’ Roast Plans.

Roasting Equipment

Sample Roasters: Stronghold S7 Pro

Production roasters: Giesen W6A

Software: Cropster Roasting Intelligence

The Green Coffees

Single Origin

Country: El Salvador

Farm: Finca Santa Elena

Region: Apaneca-IIamatepec

Altitude: 1800 masl

Varietal: Bourbon

Process: Natural

Blend

Country: Taiwan

Farm: Zouzhouyuan

Region: Alishan

Altitude: 1250 masl

Varietal: Typica

Process: Washed / Fermented

Country: Costa Rica

Farm: Nine Involment Coffee

Region: Dota

Altitude: 1650-1800 masl

Varietal: F1

Process: Honey

Country: Ethiopia

Farm: Morke

Region: Sidama Bensa

Altitude: 2380-2385 masl

Varietal: 74158

Process: Natural

Roast Profiles from the Top Three Roasters

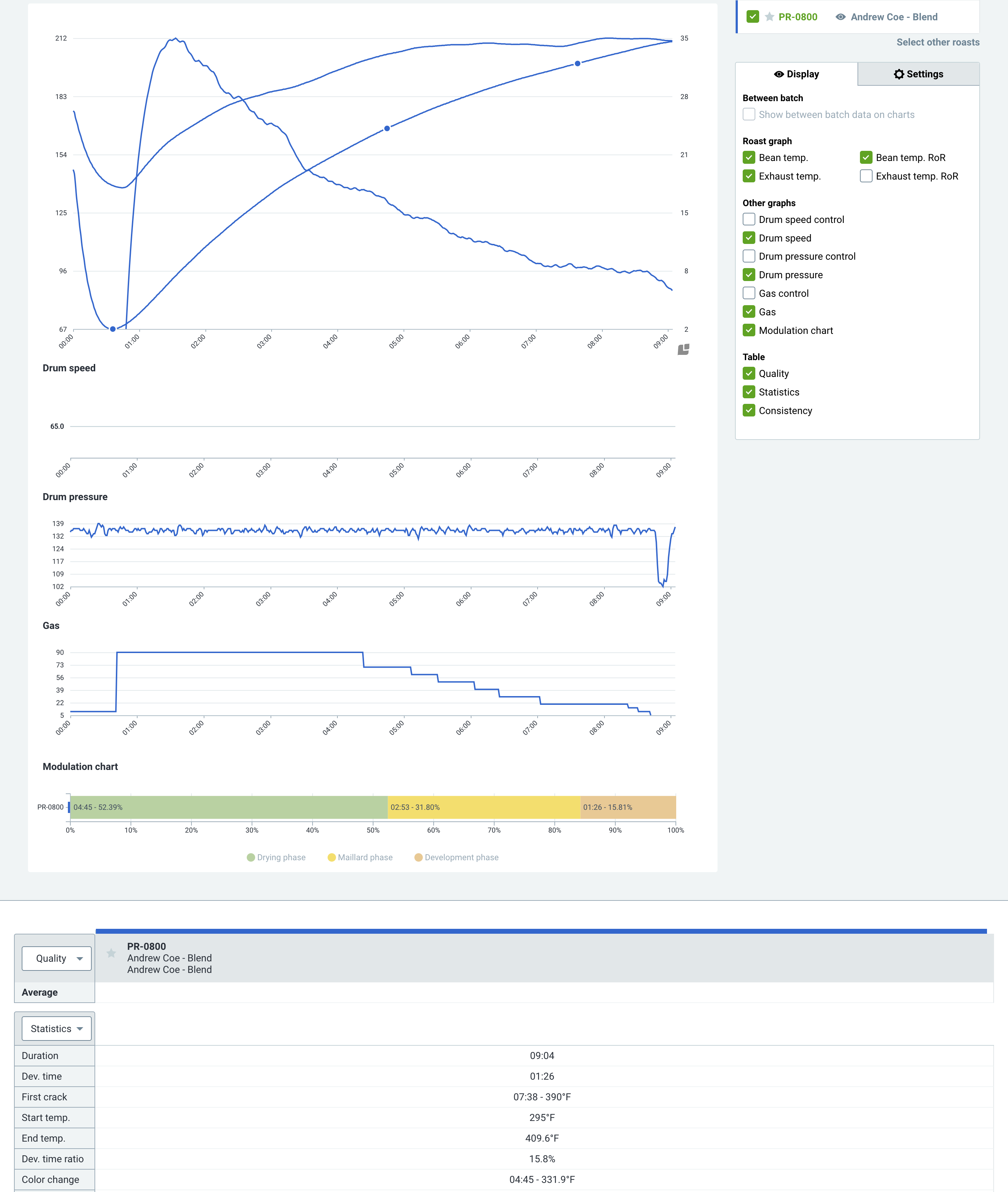

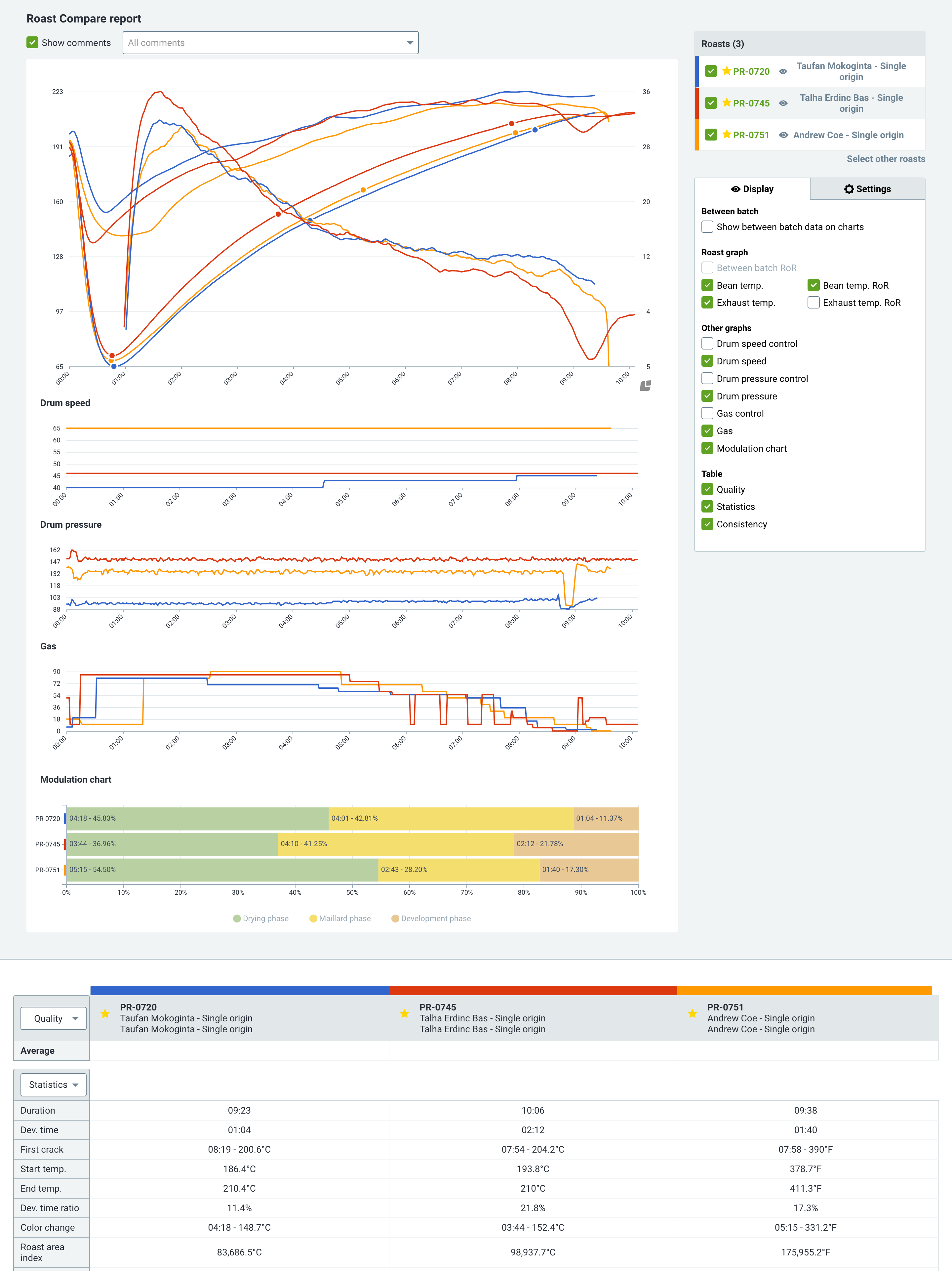

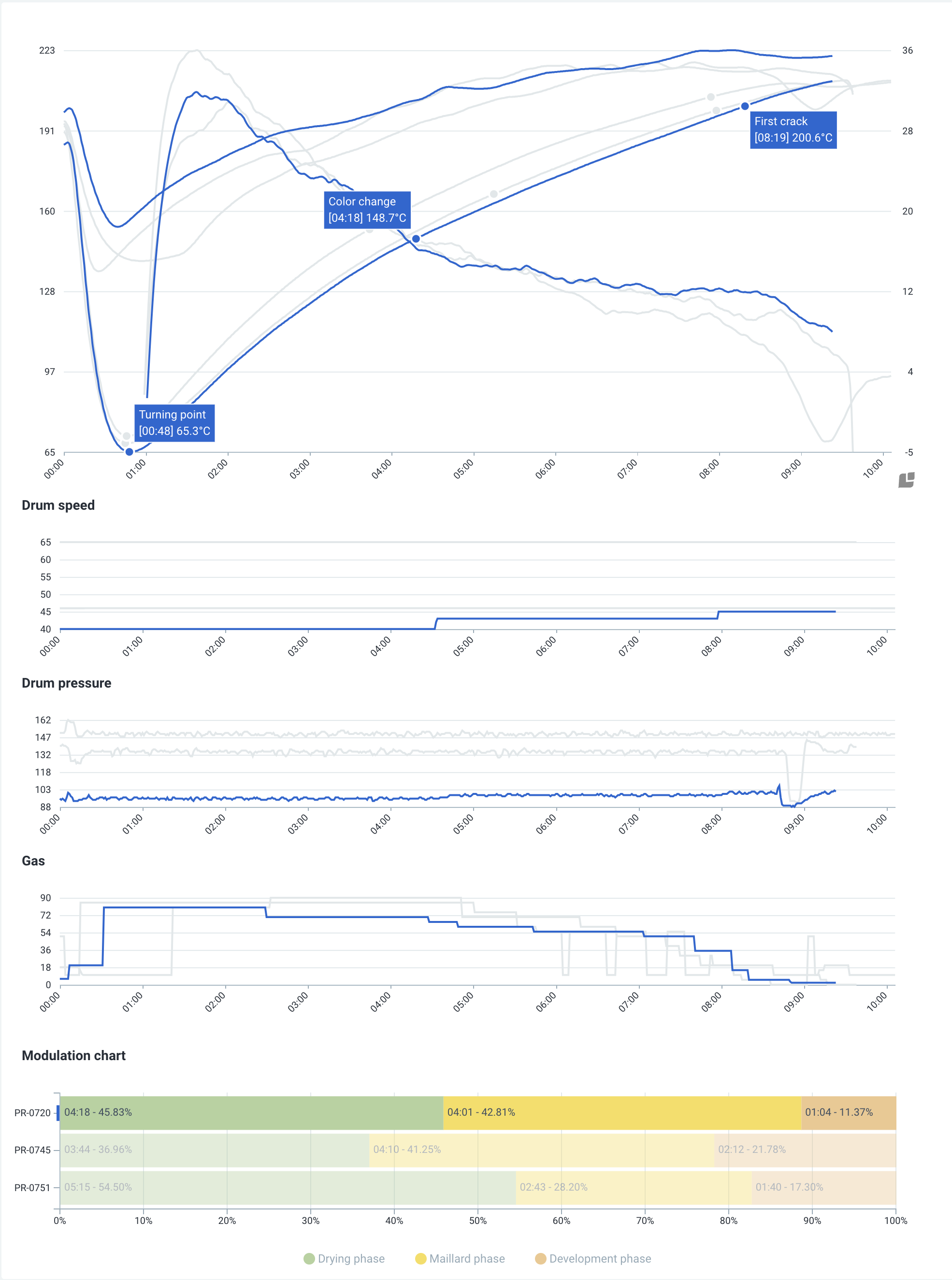

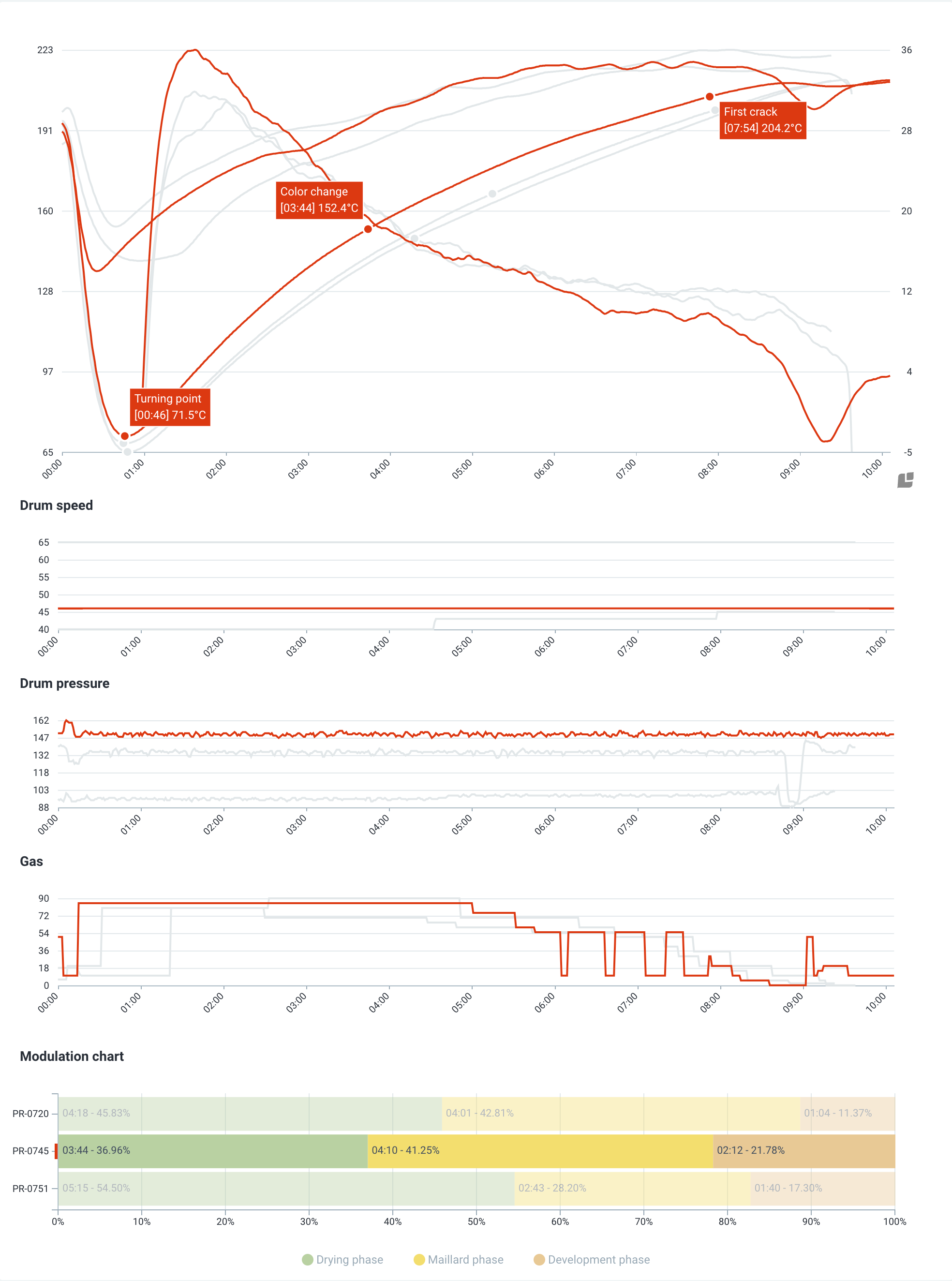

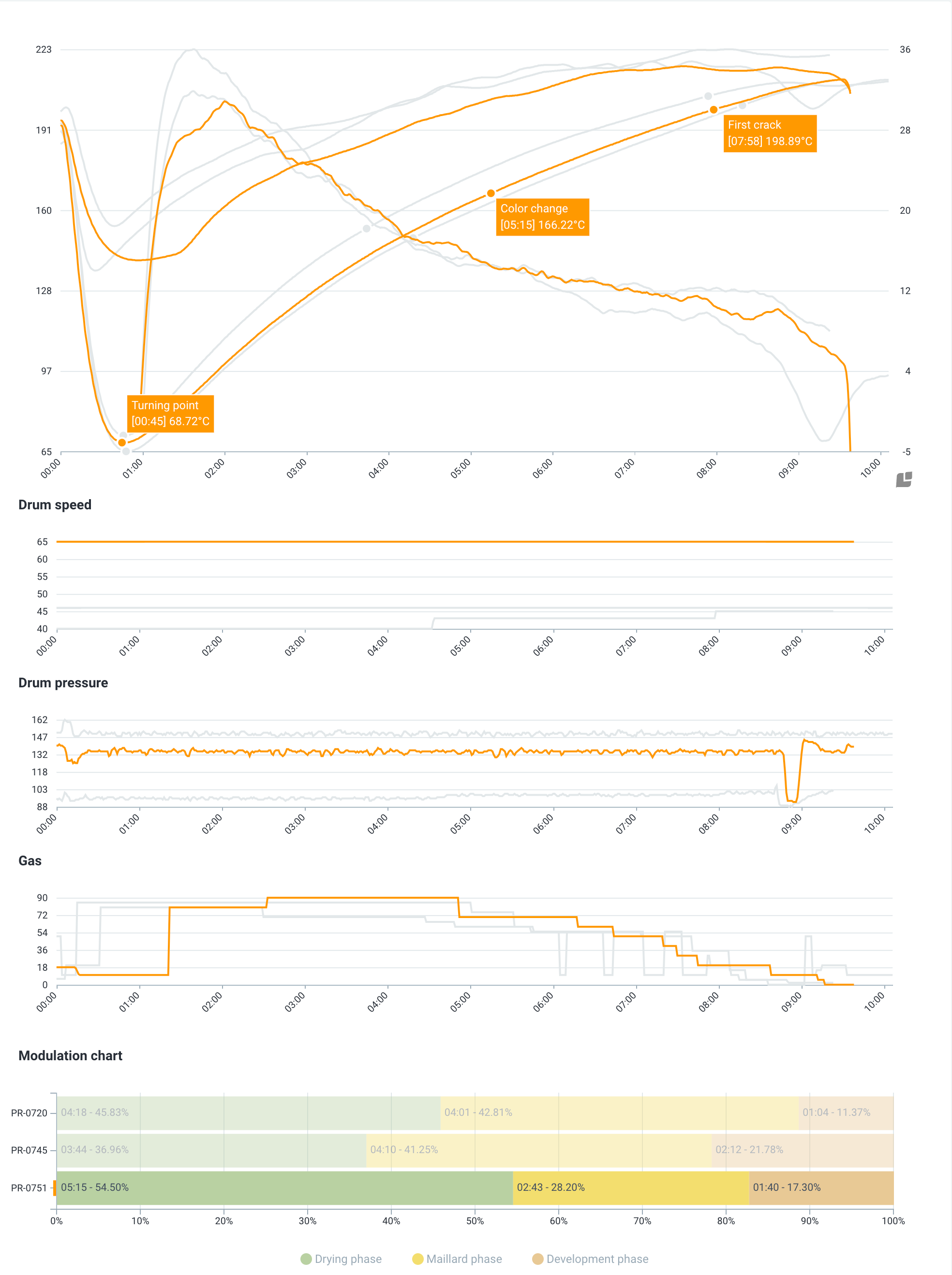

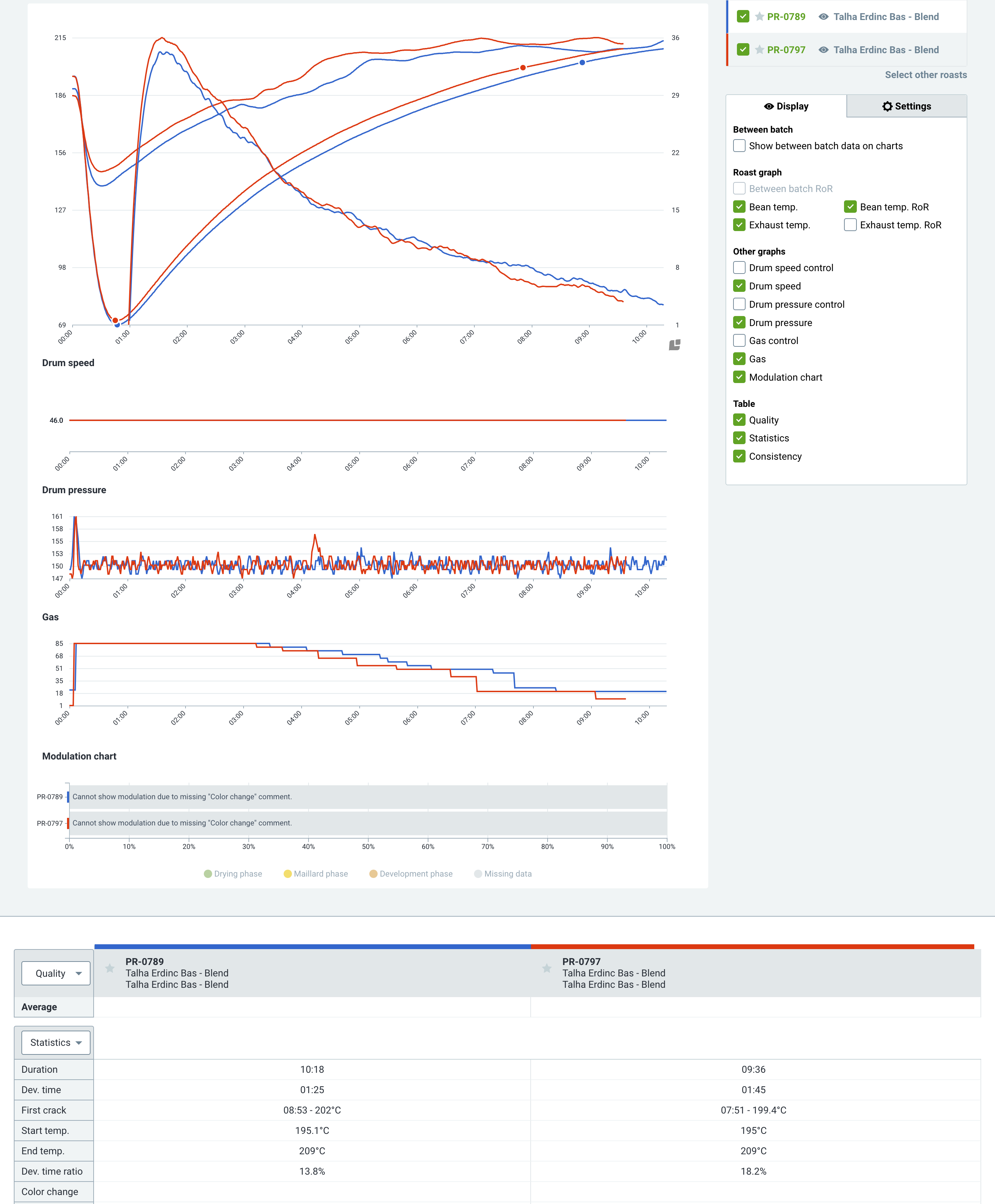

We are using Cropster’s Roast Compare function to give you an overview of all curves and roast details of both blend and single-origin roasts of the top three. This view shows all temperatures, gas, Rate of Rise, as well as the modulation chart. If you were using Cropster in a live environment, you’d be able to hover over the graphs to see temperature developments and recalculate RoR.

Some Notes:

- Competitors can, but do not have to track events like First Crack and Color Change with Cropster during competition. Luckily for us, this year all top three competitors tracked these, so we have nice, detailed data on their roasts. On the curves, these events show up as dots.

- Whenever First Crack and Color Change are tracked, the Modulation Chart can showcase the roasting phases, expressed in both time and percentage. This is the bottom chart.

- Cropster automatically logs Drum speed, Drum Pressure, and Gas changes in separate charts shown below the curves.

Roast Compare report – Single origins

1st place – Taufan Mokoginta

2nd place – Talha Erdinc Bas

3rd place – Andrew Coe

Roast Compare report – Blends

1st place – Taufan Mokoginta

Pre-roast blend of Costa Rica and Taiwan

Post-roast blend with Ethiopia

80% Ethiopia, 10% Costa Rica, 10% Taiwan

2nd place – Talha Erdinc Bas

Pre-roast blend of Ethiopia, Costa Rica, and Taiwan

80% Ethiopia, 10% Costa Rica, 10% Taiwan

3rd place – Andrew Coe

Pre-roast blend of Ethiopia, Costa Rica, and Taiwan

80% Ethiopia, 10% Costa Rica, 10% Taiwan