Managing Quality Assurance and Quality Control

| Cafe

Written by Marcus Young

Table of Contents

Cropster has tools to help manage your quality assurance and quality control, making your operation more efficient and helping you to produce consistently high quality coffee every time. It is essential to implement quality assurance protocols to effectively organize your roastery and cafe to prevent quality issues from arising in the first place.

When a roastery fails to deliver the quality their customers expect, the results are expensive. Lost customers, smaller order sizes, and wasted product are just some consequences. In day-to-day production operations, you need tools that help you achieve consistent quality every day. Cropster assures you catch any potential quality issues early, before your customers do, so that your customers are satisfied.

Quality Assurance (QA) versus Quality Control (QC)

Quality Assurance are all the steps and processes in place to ensure products are made and produced according to your standards. In a coffee roastery, quality assurance would include your standard operating procedures. For green coffee buyers, this would include flavor profiles, sensory scores, target use-by dates for green coffee lots, and other elements related to the quality and profile of the coffees being sourced.

Cropster simplifies quality assurance of your green coffee purchases and quality control of your green inventory

For roasters, this could include setting blend recipes, reference profiles, and targets for roast level and other details. Your production team establishes guidelines for packaging soon after roasting, grinding according to specific requirements, and staging and packaging coffee for delivery following set guidelines.

Establlishing roast profiles and setting relevant profile goals are an important quality assurance step, made easy with Cropster.

Other procedures would include standardized times between sample roasting and cupping, between batch protocols on your roasting machine, establishing a consistent preheat procedure for your roasting machine, and outlining cleaning and preventative maintenance and cleaning tasks for equipment like weigh-and-fill machines and grinders.

Establishing and tracking between batch protocols are an important element of quality management

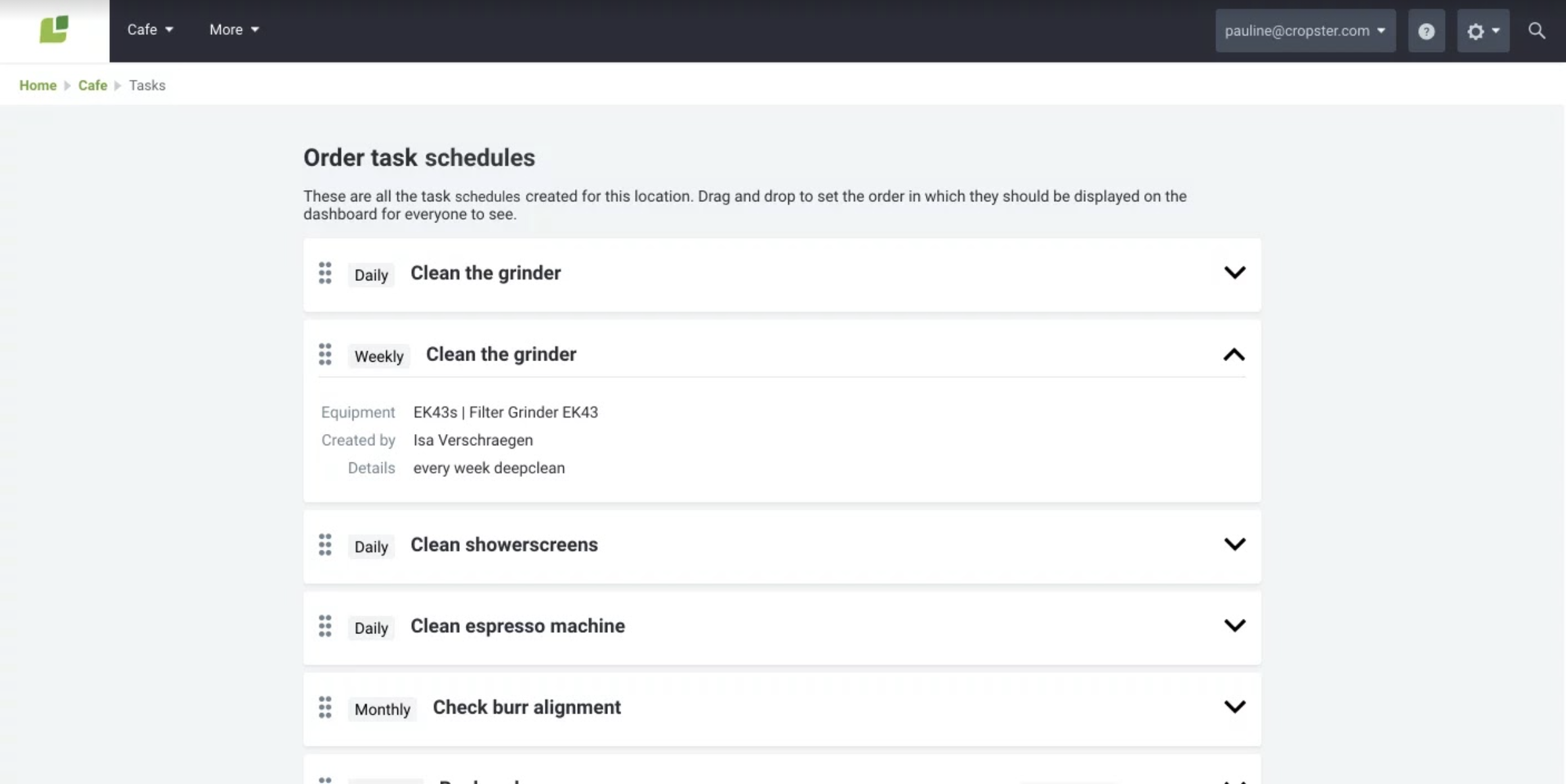

In your cafe, quality assurance would include cleaning and preventative maintenance tasks, establishing a set number of days to rest the coffee and use-by dates for coffee served as espresso (which might differ from the use-by dates for coffee served as filter coffee). Quality assurance also extends to establishing target brew recipes and flavor profiles for each coffee, clearly articulating recipes for your signature drinks, and setting standards for every detail of your operation.

Establishing retail check lists in Cropster Cafe helps track all of the little details necessary for quality coffee are in place

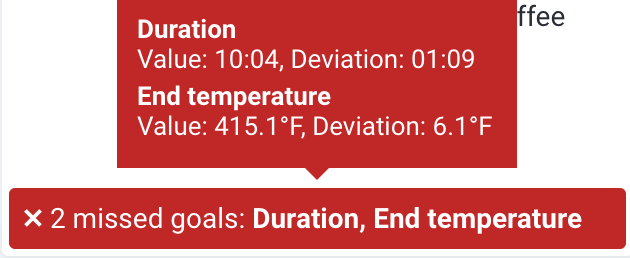

Quality Control is the process of inspection and analysis of your final product to ensure it meets your specifications and standards. For your roastery, this would be establishing roast goals based on acceptable deviations from the saved profile. These could include total roast time and end temperature, or the time (or percentage) of each development phase during the roast. Others often reference whole bean and ground roast colors, weight loss percentage, and sensory characteristics of the coffees.

Roast reports and viewing failed goals are an easy way to view roast batches requiring extra attention by your QC team

Production staff should analyze grind particle size, assess packaging integrity, pull product to taste for shelf life and product degradation over time, and analyze your coffee to be sure that every production step is geared towards releasing coffee to customers that meets your articulated product standards. This could include cupping production batches, but also preparing brewed samples and espresso extractions to assess final quality from the perspective of how your customers are preparing the coffee.

Tools in Cropster for QA and QC

To help roasters accomplish QC tasks, Cropster provides the ability to compare roasts and report on failed roast goals. Cropster cup includes industry standard cupping forms and custom QC forms. Ultimately, your QC procedures like physical analysis, green grading, and cupping scores link to specific sample lots (SGs), green lots (PGs) and production roasts (PRs). This allows roastery managers to track quality over time, identify the stage in production which caused the issue in the first place, and implement tighter controls to avoid production losses in the future.

It is important for production teams to stay organized, label every batch, and track coffee through the production process. One way Cropster does this is to automatically assign individual IDs for each sample (SG codes), green coffee in your inventory (PG codes), and roast batch (PR code). The PR ID can be used in several applications like creating production cuppings and tracing coffee lots to the end-user if ever there is a quality issue.

One best practice is to pull a sample from every completed roast, label the sample (and the larger full lot). Roasting Intelligence makes it easy for you to print your roast labels as soon as a roast is completed, capturing key roast information to review later during your cupping. Printing sample labels saves you time and gives you more complete batch information than handwritten labels.

Print sample labels directly from Roasting Intelligence to give you comprehensive batch information for each roast batch

Once labeled, your production team can analyze the samples’ roast color, weigh the entire lot, and record the post-roast weight (Cropster calculates your weight-loss percent for you), and perform other relevant tests. This data can be entered directly into Roasting Intelligence during the production day, or can be entered later in Cropster’s c-sar database. Once the sample is cupped, that information is logged and tied to the sample PR ID, giving you complete quality visibility in your centralized c-sar account.

Cupping your coffees and logging your cupping sessions is the best way to improve quality, maintain consistency, and continually learn how decisions in roasting and production impact the final cup quality. Cupping production batches is simple with Cropster, with multiple industry standard cupping forms available, and the option to request custom cupping forms.

Once you have collected your samples and are ready to begin a production cupping, you can simply open a new cupping session, select your cupping form and add the coffee lots (based on PR codes) directly in the dropdown. Your team can easily open Cropster Cup on a mobile device and easily enter in their scores and personal notes and flavor descriptors.

Cropster cafe loggs key brew parameters and provides detailed reports of every single extraction

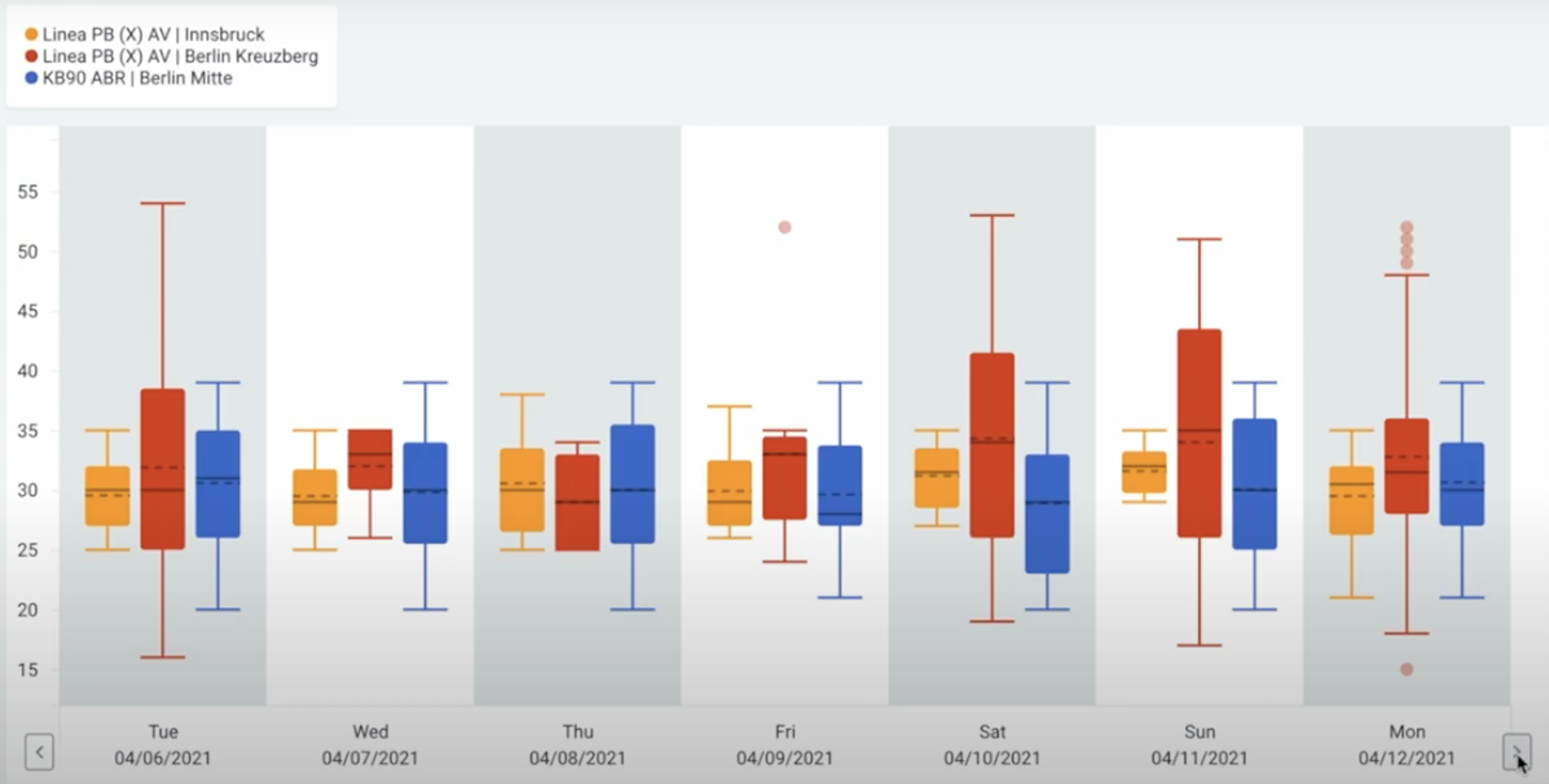

Cropster Cafe represents new opportunities for retailers to assess quality in the cafe. Retailers can establish set recipes and compare the performance of the coffee against flavor expectations and brew parameters. Roasters who operate their own cafes can see how their roasts perform at the cafe. Cropster cafe accomplishes this by logging key brew parameters like brew time, shot volume, flow meter rates, and brew temperature and providing detailed reports of every single extraction.

These reports show extraction variations day by day, machine by machine, and location by location. Cropster Cafe makes it easier than ever for coffeehouses and roaster/retailers to assess quality from real statistical reports of every extraction, moving away from anecdotal reports of quality to measurable standards.

Investing in Quality

Implementing quality assurance and quality control at a roasting company takes a concerted effort and attention to detail. It requires analyzing processes and systems to ensure your company can reliably produce coffee at your target quality. To do this, roasters need to consider every stage of the production process.

Assess brew quality across multiple machines and multiple locations, spotting quality issues early and giving your customers consistent coffee no matter where they’re located

Quality control is the post-production side of quality management, and involves installing procedures to test and assess production samples, comparing them to your product specifications. Cropster’s tools for coffee labs, green buyers, production managers, and coffee retailers are one element of a successful quality management system. The benefits of these investments in quality are significant. Consistent products mean happy customers who order consistently over a long period of time.

Quality management, especially establishing quality assurance systems, can lead to fewer issues with quality control, less product waste in production, and fewer rejected lots. The high-costs of coffee for many roasting companies and the labor involved to roast and produce your coffee equates to a high-value for every single roast batch. With systems that ensure fewer failed batches, roasting companies realize real cost savings. Cropster’s roast profiling tools, cupping reports, and simplified quality analysis with Cropster Cup, makes these processes easy and efficient to implement.

Equally important for retailers is having a reliable product from roasters and then executing the brewing of that coffee consistently. When retailers implement Cropster Cafe, they have tools that link the product quality at the roastery to the products on their shelves. They also have powerful tools to establish tasks for equipment maintenance, create brew recipes, and report on every extraction.

The result of quality management systems is better coffee, more consistently, with repeat customers for your great coffees.