We are thrilled to announce that starting today airflow control and replay is now available to Cropster users starting with the Probatone 2 and the brand new Probat PIII series machines. If you’re roasting on another machine, all good, like gas control and replay we’re already working with other manufacturers to roll this out to a variety of machines. Is yours on the list? Visit our handy Connects to Cropster page for full machine & manufacturer details. We’ll begin adding airflow control to more machines soon so watch that space!

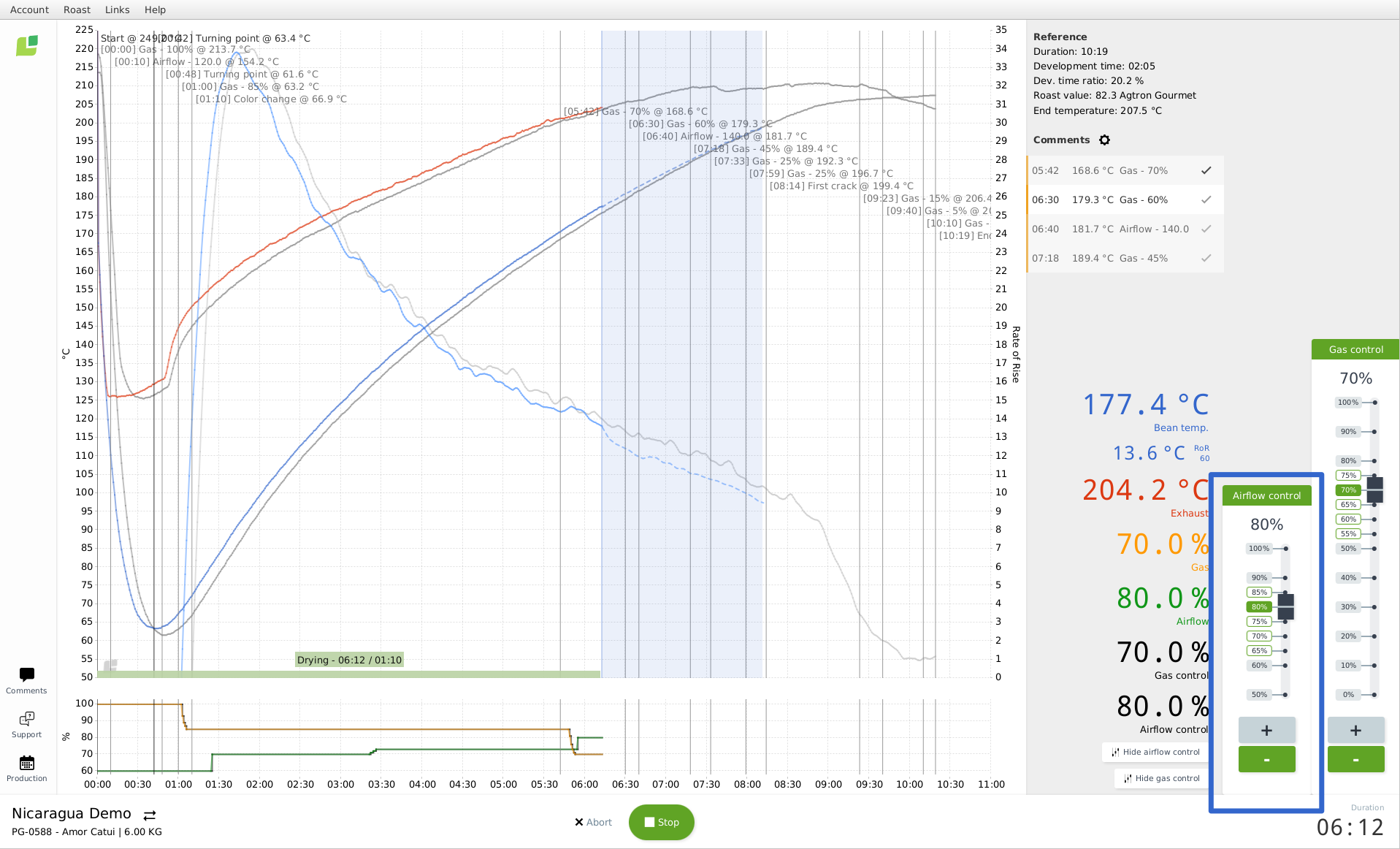

Integrated airflow control and replay means Cropster customers can now control airflow from within the Roasting Intelligence (RI) using a slider. It works just like integrated gas control. This step also makes it possible for Cropster to add replay functionality on airflow starting with Probat machines with many more to come. It also means more control from a single, simple interface and of course with replay built in, an easier route to consistency across roasts! That’s because airflow control data (like gas control) is tied to your roast profile. So you can set that reference profile and let Cropster repeat your exact airflow adjustments during the roast.

Other benefits include more time for roasters to focus on other parts of the roasting process and training/onboarding. We’ve heard repeatedly that semi-automation makes this process much easier for businesses (along with features like AI driven roast profile prediction). Like gas control, airflow automation is simple to setup and run. Just a few simple clicks and it’s good to go. Simply go to preferences in Roasting Intelligence and you’ll see a setting to turn it on. Once airflow control is enabled you’ll see the slider in the RI and you are good to roast!

Using airflow control with Cropster’s Roasting Intelligence

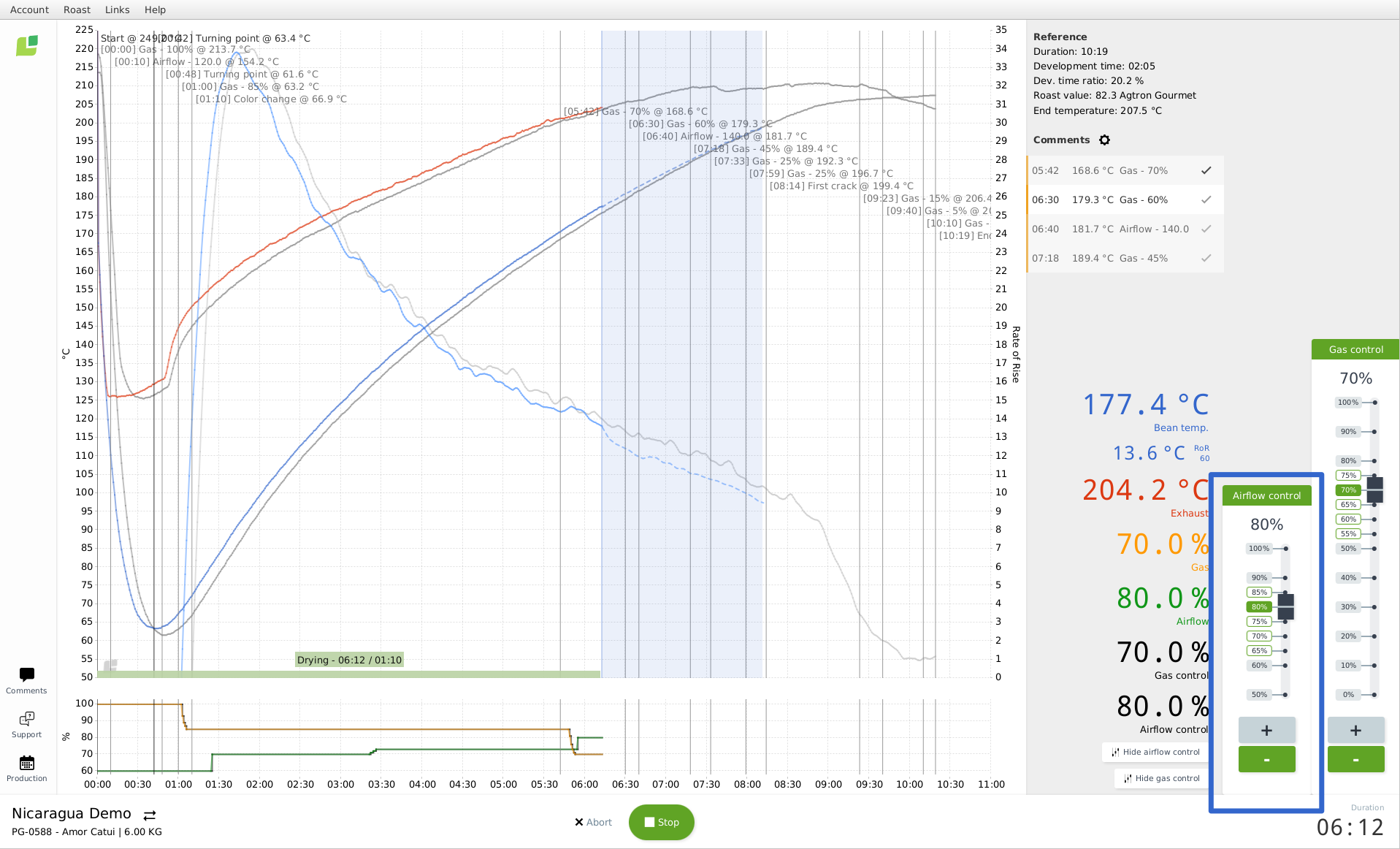

After you are done roasting, you can visualize and analyze all airflow and gas changes that were made during your roasts.

Airflow control charting and analysis

With the addition of airflow control we are taking another big step towards a common customer request – moving roasting control to a single, simple and intuitive interface. Our next focus is drum speed and work has already begun!