Connecting your roast machine to Cropster quickly and easily

| RI

Written by Taylor Wallace

Table of Contents

Let us start by saying: If you can roast with it, you can use Cropster with it. Here is a list of just some of the roasters that we have connected to Cropster already:

Giesen – Loring – Diedrich – Probat – Coffeetool – Proaster – San Franciscan – IMF – Bühler – Toper – Has Garanti – Atilla – Garanti – Petroncini – Joper – US Roasters – Gothot – Ambex – STA – Renegade – Brambati – Huky – Quest – Coffee Tech – Roastmax – Victoria – Bella Taiwan…

With that being said, let’s go over how you may go about doing this with your machine.

Method One: Plug & play

Cropster provides plug & play, no-hardware solutions for the following roast machines:

- Loring Smart Roasters

- Giesen Coffee-Roasters built after June 2014 (ex. W15A)

- Coffee Tool Roasters with a PLC

These machines do not require any more setup than simply plugging an ethernet cable directly from your roaster to your computer (although some manufacturers do charge for an unlock code to do this). By doing so, we connect to the machine’s computing unit directly. This setup process takes seconds.

Also, many new machines (Proaster, San Franciscan, Diedrich etc.) come standard issued with connectors which makes the setup process as simple as connecting your roaster and computer via USB cable.

Method Two: Via the Cropster Connector

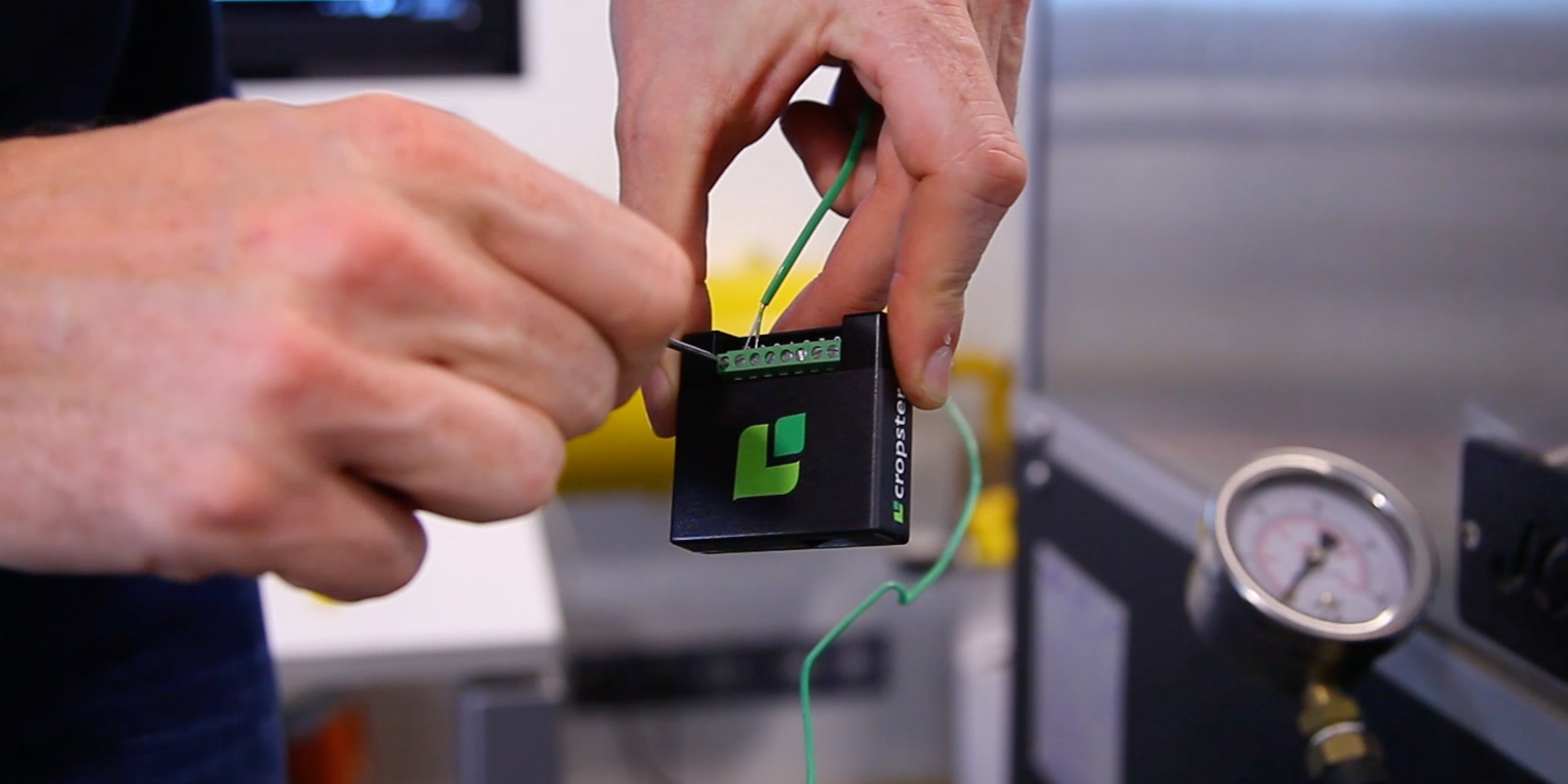

Good news! You’re about to learn a few interesting things about your roast machine. First, Cropster can integrate with any other roaster that has ungrounded thermocouples (K, J, E or T type) or RTD temperature sensors via a Cropster connector – what does that mean? Read on. It’s simpler than it sounds. These terms cover 99% of the roast machines we know of. The Cropster Connector is a small device that can track up to four temperatures at the same time which equates to either one production roaster or multiple barrels on a sample roaster. Hooking up your roaster to this connector is quick and easy and takes 30 minutes or less including time for a coffee.

Here is a little bit of information on each type of setup.

A) Ungrounded Thermocouples: K, J, E and T

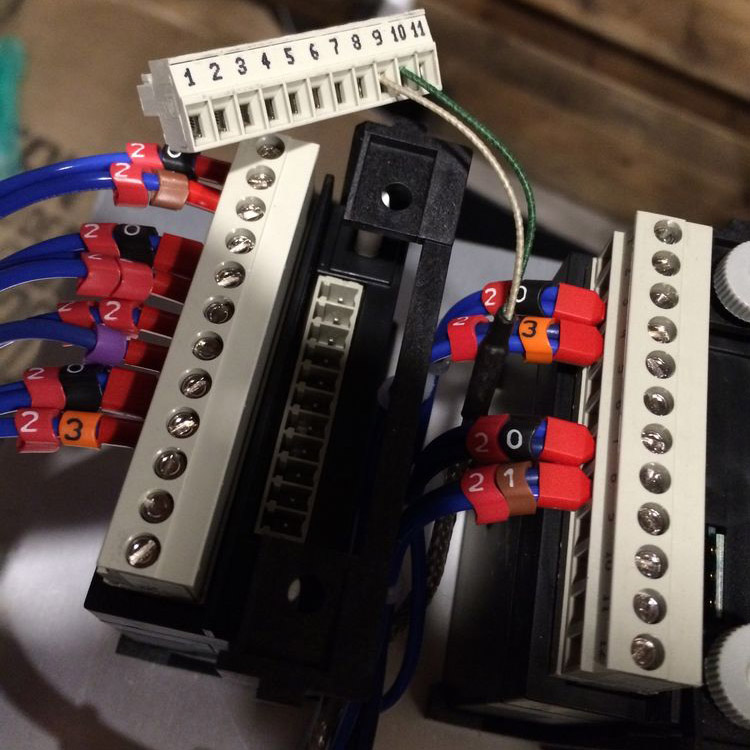

The vast majority of drum roasters use K or J type thermocouples–K type being the more popular of the two. If you aren’t sure what type of thermocouples you have, send us a photo of your probe wires (similar to the photo below) and we’ll tell you what you have. To find them, simply locate your temperature probe and follow the wires from it to the other end. Then take a photo of the wires at their connection point. Their colors will tell us more about their type and let us know what type of wire we might need to send for you to extend this connection to the Cropster Connector. Also, to speed up the process, please let us know the make and model of your roaster, and the year it was produced.

Above: K type thermocouples in a Probatino. The green/white insulation colors indicate that these probes are manufactured to European standards and are K type.

Above: Another example for K type probes. Red/yellow colors indicates American standard K type probes

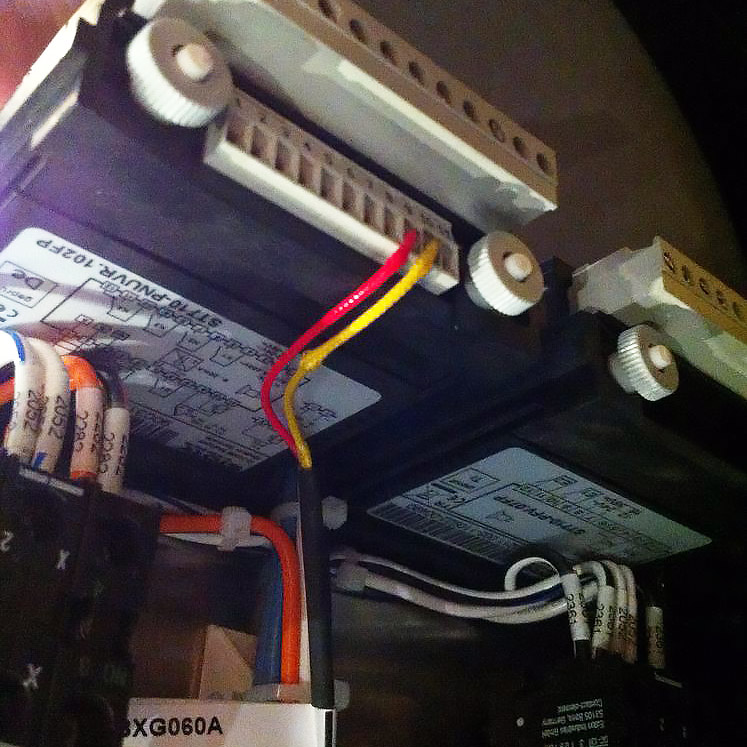

B) RTD Sensors: PT-100/PT-1000

Unlike thermocouples, extending an RTD probe signal from a digital readout and feeding it into our Cropster Connector is bit more complicated. Bypassing your current digital readout can affect emergency shutoff and alarm systems in some machines. Because of this, we recommend installing a replacement dual/duplex probe. That way you gain an extra set of leads dedicated to Cropster while the other set feeds into your existing system. We believe this is a win-win for you. Dual probes can be sourced pretty easily at reasonable prices.

Above: A standard RTD connection in a refurbished old roaster. RTD wires typically have 2-4 wires per readout with red/white insulation and only require 2 for a Cropster readout.

If you can roast with it, Cropster can help you get more from it.

Connecting your roast machine to Cropster is the first step toward leveraging green coffee and roast production management tools, roast profiling tools, roast compare reports and QC features. The minutes invested in connecting a roast machine to a tool like Cropster will pay off every time you use the machine and every time you work on a process around the machine. That’s the beauty of connecting your roast machine to a system that can grow with you and your business.

Still happier handling the beans than dealing with the tech?

We have a support team standing by who are more than happy to walk you through the entire setup process. We will even help you source replacement probes and hardware if you need it! Just contact us and we’ll get you up and running asap.