Back to Basics: What is a Profile?

| Cafe

Written by Marcus Young

Table of Contents

For example, imagine you offer your customers a single origin Rwanda Twongere Umusaruro, which is very popular. If you follow a roast to order production system, you may sometimes need to roast full batches of this coffee, other times ½ batches, or even sometimes a minimum capacity batch. To ensure product consistency and simplify your production, you create multiple profiles for the same coffee in different batch sizes. The ultimate goal is to produce a coffee that tastes the same no matter the batch size; however, the profiles used to accomplish this might look quite different, especially your charge temperature, machine settings like drum speed and gas percentage, and even the anticipated time and temperatures when various milestones occur during the roast.

To make managing these situations easier, we implemented profile groups in Cropster. If you track your product orders in Cropster, you will soon be able to link a particular product to the relevant profile group in order to track your roasted inventory on hand and schedule further roasts in order to fulfill those orders.

Read on to learn more about how a variety of roasting companies and industry groups define profiles, consider the various elements of profiles, and the way Cropster is simplifying and improving profile management.

What Is a Profile?

In roasting, everyone talks about roast profiles, but we all use the term differently. Defining what we mean by roast profile is important to aid our discussions of roasting, how to achieve our roast goals, and how our specific approaches to coffee reflect the identity of our companies.

Within Cropster, we use the term profile in some very specific ways to describe how a specific batch of coffee is roasted. As an industry, we use profile for a number of things, such as to refer to a sensory profile for our company and coffee, a recipe for roasting, and also for a roast that is underway in our roaster. Roasters will also use the term profiling a coffee to describe a product development process, as they are trying different roasting approaches to identify the sweet spot for any given coffee.

Based on the results of user surveys, we know that many of our customers think of profiles in several ways – from recipes for crafting coffee, to specific time and temperature targets, the roast color of a given coffee, and / or the final sensory milestones in a finished product. Within Cropster, we can accommodate a variety of definitions, but also think it’s important to outline some of the most common elements of a roast profile.

Elements of a Profile

In the most basic terms, a profile is a recipe. It’s a series of steps and characteristics that describe how a coffee is roasted. Consistency is a key goal of most roasting companies. Achieving consistency for any given product is a combination of artful coffee buying and blending, and, equally important, roasting that coffee the same way every time. When we talk about a roast profile, we are talking about all the elements of that recipe. The ultimate goal of a recipe is to craft a product that tastes consistent and meets defined sensory characteristics for aromatics, flavor and taste, mouthfeel, acidity, and balance.

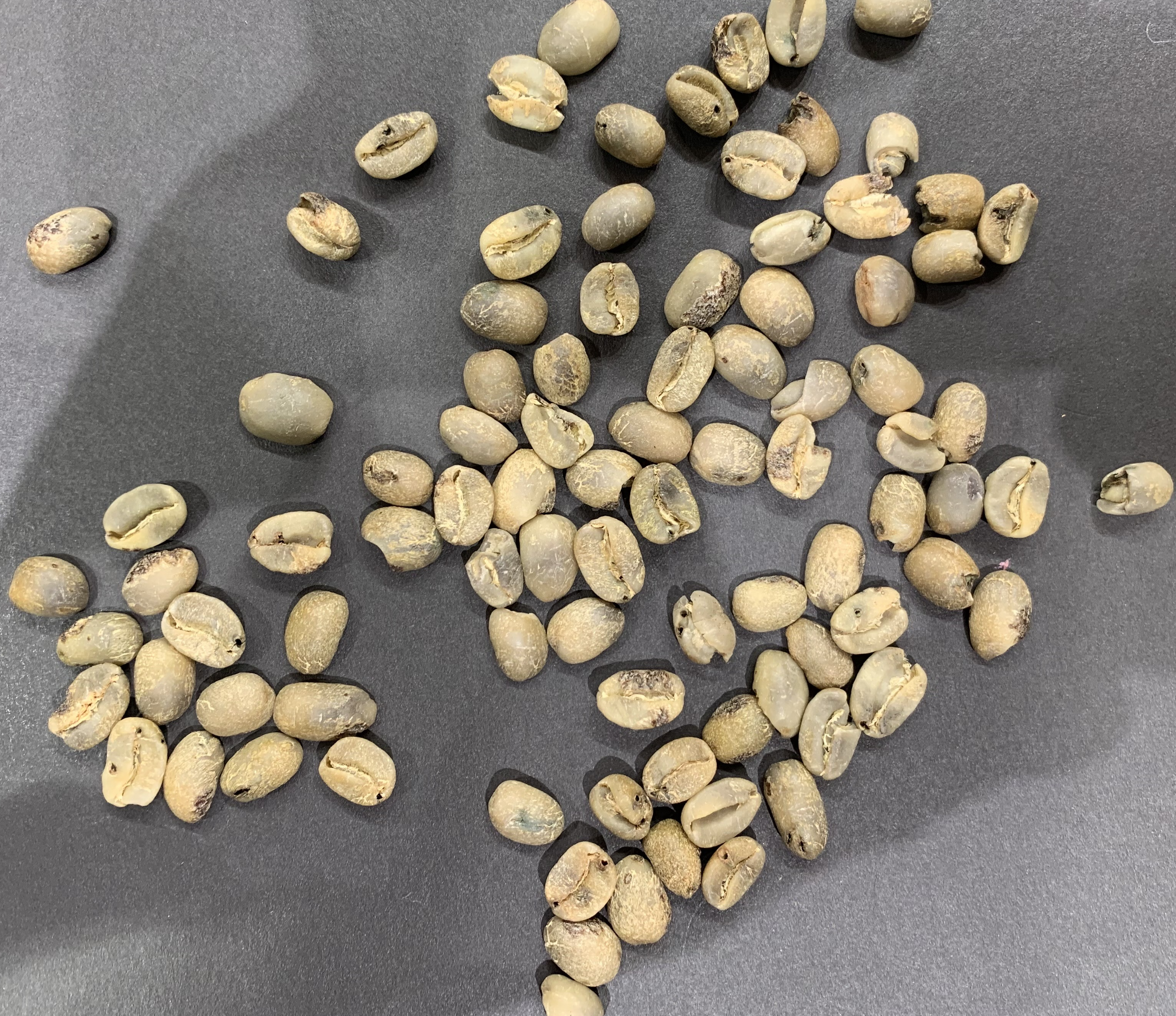

An essential part of recipes for cooking food are the ingredients. With a coffee profile, your green coffee – either a single origin offering or a blend of coffees – is the primary ingredient. Some roasters blend their green coffee prior to roasting, others roast each component individually and then blend after roasting. Roasters argue passionately about both approaches, and we’ll take up blending in a future blog post. No matter your approach, the physical characteristics of the green coffee you’re starting with are an essential component of your profile. These can include bean size, bulk density, moisture content, water activity, processing method, origin, and more.

The environment of your green coffee storage and roasting room are also important for your profile. If you established your recipe at the height of summer when your green coffee storage room and roastery were really warm, your coffee will be warm when it enters the roaster and your inlet air will be warm entering the roasting machine. Compare this to the wintertime when your facility may be colder when you need to account for cooler coffee and colder inlet air temperatures in your roasting controls. Similar changes in barometric pressure and humidity can wreak similar havoc on your profiles.

If you roast the same coffee at different batch sizes, the size of each batch becomes an integral part of your roast profile. A smaller batch will require less heat and energy than a larger batch. The airflow and relationships between convection and conduction in the roasting drum will be dramatically different for a full size batch versus one third of a batch. Batch size will inform all of your roasting controls, including your gas pressure and flame to air flow and drum speed.

Profiles and Roasting Outcomes

There are several measurements you can take from your roasted coffee that are important elements of a roast profile and key indicators that the coffee was roasted consistently to your recipe, and is likely to result in a similar flavor profile. The key measurements are roast color and weight loss percent from green to roasted coffee. Some roasters will also compare density (volume of coffee for a standard volume – e.g. grams per liter) from green to roasted coffee or record additional data.

Roast color of your whole bean coffee and ground coffee is a key indicator of consistency. This measurement requires specialized measuring tools from companies like ColorTrack or Agtron. Roast analyzers from different companies will often use proprietary scales, making it difficult to compare results from one system to another. Because roast color changes with the amount of time off roast, measurements need to be taken at the same time after roasting each batch.

The protocols somewhat depend on the type of color meter you use, but it is essential to grind consistently, prepare each sample using the same tools and protocols, and log the resulting information. In the absence of a roast color meter, some roasters have adopted the SCA Color Classification System based on the Agtron Gourmet scale – though there are serious limitations to this approach, including the complex and time-consuming protocols required for this measurement.

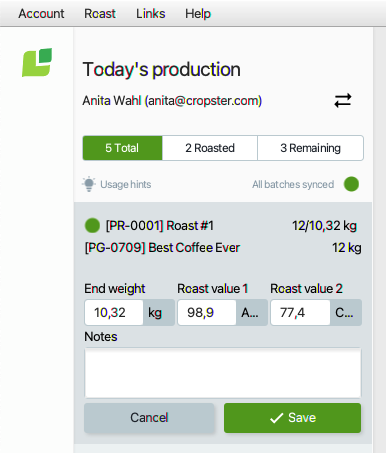

Cropster Roasting Intelligence makes this easy, giving you a chance to record two separate roast values – one for whole bean coffee and another for ground coffee immediately after roasting. You can also log your roast value later from your web browser by calling up a roast and entering this information. Once you log this information, you can use Roast Goals to report success or failure against this metric.

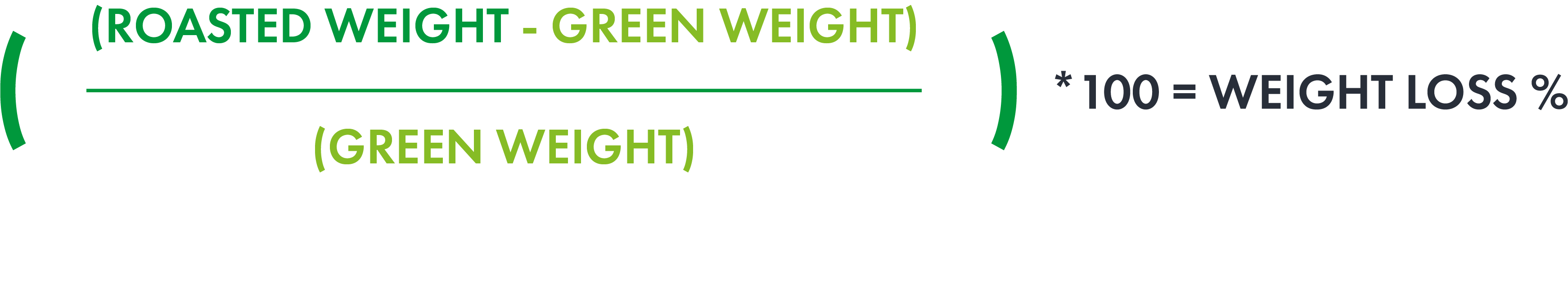

The percentage of weight loss is another essential element. Not only does this tell you how much roasted coffee you actually have to sell, it tells you if conditions were generally the same in the roaster from batch to batch. As described earlier, consistent batch size is part of a coffee’s recipe or profile (or reference profile in Cropster). Each batch of the same size should weigh the same once it’s roasted. To take this a step further, and to account for varying batch sizes of the same coffee, most roasters record the percentage of roast loss. The formula for this is:

Cropster simplifies this calculation for you. An element of Cropster’s reference profile is the green coffee batch size, and Roasting Intelligence has a field to record end weight after roasting. Cropster takes care of the formula and calculates the weight loss percentage, which can be used for reporting against roast goals.

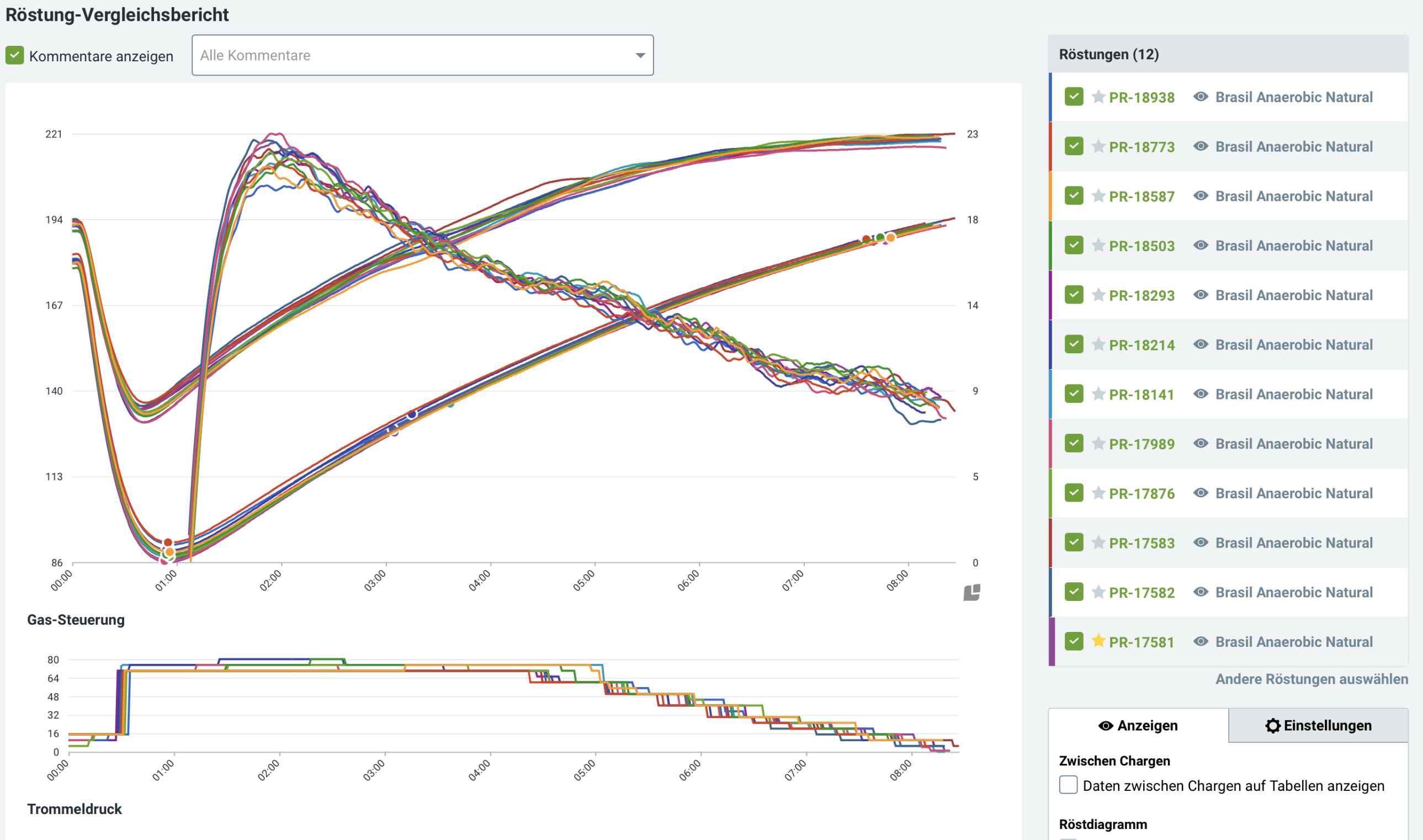

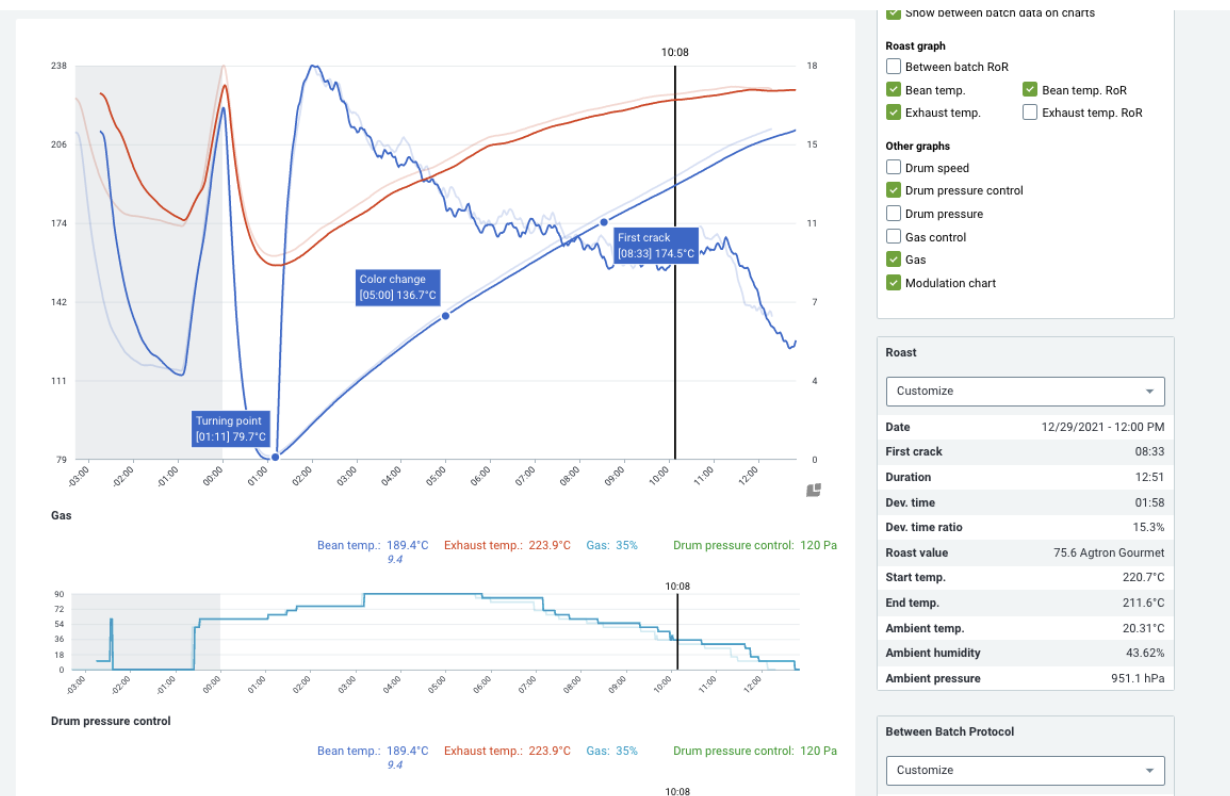

Roasters use Cropster Roasting Intelligence to record the time and temperature curves during a roast; the rate of rise; and changes to the roasting inputs, including gas, airflow, and drumspeed. Roasters also log meaningful sensory information about each roast, including time and temperature of yellowing, first crack, and second crack. With a roasting recipe, or reference profile, roasters can compare the current roast to the set profile.

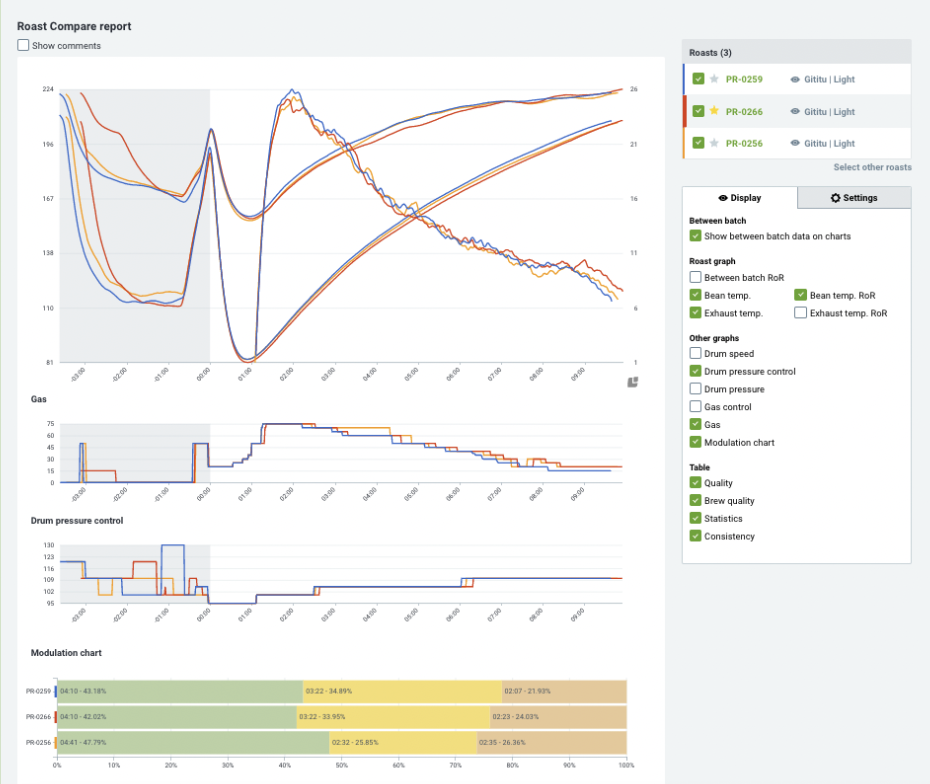

Based on the data being collected, roasters will monitor the development phases of each roast, tracking the time (and the percentage of time over the total roast), and comparing that to their recipe. This is the modulation chart when you are viewing roasts in Cropster. These phases include:

- Drying time, or the time from when you charge the green coffee into the roasting drum until yellowing occurs.

- Maillard time, which is the time from the start of yellowing to the start of first crack

- Development time, which is the time from the start of first crack until the end of the roast.

This process is complicated because as an industry, we have no firmly established and communicated standards for what makes up yellowing in the roaster, or when roasters record first crack (e.g. is it the first sign of a coffee bean making the familiar cracking sound, is it when there are several beans cracking all at once, or is it based on some other sensory feedback like the smell of the coffee in the trier?).

Ultimately, individual roaster operators need to be consistent with how they record these sensory phases, and lead roasters must train their team on what makes up these milestones. Alternatively, you can set up Cropster Roasting Intelligence to Auto-mark development events based on bean temperature – which takes the guesswork out of marking events, and instead records yellowing, first crack, and second crack based on bean temperature.

Towards the end of a roast, roaster operators monitor the target end time and temperature, the development time, and the color and aromatic development to determine when to end the roast and discharge the coffee into the cooling tray.

After completing a roast, the specific profile ends, but then the between batch protocol (BBP) starts. Having a protocol for what happens with the roaster between batches ensures that the conditions in the roasting machine are consistent at the beginning of each roast. You can read more about BBP from industry experts like Rob Hoos, Anne Cooper, and Scott Rao in our educational article, Between Batch Protocol For Coffee Roasters.

A feature that makes it easy for lead roasters and roastery managers to assess the success of profiles is the ability to assign roast goals to each profile. You can establish roast goals for almost any element of a roast, including time and temperature metrics, rate of rise, development time, total roast time, end temperature, and even roast color and weight loss. Roasters can see which roasts met all the goals, and which roasts didn’t measure up, simply by reviewing the list of completed roasts or a production report.

The ultimate test for a specific roast batch is the result of the cup. Establishing a protocol for assessing roasted coffee quality is essential. Some roasters will pull samples directly from the cooling tray to cup later – assessing the cup quality of every single batch. Other roasters will assess a statistically significant number of samples from each production day. The choice of how to cup and score production batches varies. Some companies employ an alternative cupping form like the World Brewers Cup form, or implement a simplified pass/fail methodology. Some companies cup coffees following SCA cupping standards, others assess brewed coffee and espressos, while others take a statistical approach with in/out and triangle tests. No matter what method you choose, Cropster Cup and our quality control modules have tools to track your assessments and tie them to production batches. We will cover roasted coffee QC in a future article in the coming months. What’s important is that you are regularly tasting your coffee and assessing quality and consistency in the cup, along with using the data captured while roasting, to ascertain your success with profile roasting.

Within Cropster we are always making improvements to our software to be more relevant and responsive to the input of our customers. Profile groups are one way we’ve done this, allowing you to group together profiles with similar goals (e.g. roasting the same coffee for the same product with different batch sizes), and then use the tools within Cropster to assess individual roasts against the saved profiles. The results of each roast, assessed through data collection at the roaster and physical and sensory analysis of the final product, are all captured within your Cropster account for easy reporting, future reference, ongoing learning, and quality improvements.